Tilak Nagar, Indore, Madhya Pradesh

- GST NO. : 23ABTPJ0705D1Z3

Cost Saving & Processing Machines

Leading Manufacturers, Exporters, Wholesaler and Retailer of Dry Electrodes Flux De Coating Machine, Wet and Dry Flux Pulverizer, Wet Electrodes Flux De Coating Machine and Wire Cleaning Machine from Indore.

| Business Type | Manufacturer, Exporter, Supplier |

| De-coating Machine Weight | 300 to 350 Kgs |

| Length | 1000mm |

| Width | 800 mm |

| Height | 900mm (Approx.) |

Main Features :

The machine is robust and does not require foundation.

The System have Twin Set of Machines. Main machine :

De-Coating M/c - De-coat the electrode and

- Cleaning M/c - Clean the wire.

- The machine is maintenance free.

De-Coating Machine fitted with Two HP Motor with high ratio Gear Box and Cleaning Machine fitted with One HP Motor with high ratio Gear Box.

The electrode loaded in the Hoper and Pick-up Roller, picks-up electrode one -by- one and send to the De-coating station. At De-coating Station it de-coat the electrode at the faster rate and it is a continues process. After De-coating the wire claimed is with a fine layer of flux and need to clean.

The Cleaning machine cleans the wire and it can be re-usable for production.

The Flux reclaimed from de-coating can also be reused.

The machine can be used for De-coating of the WET Electrodes. However the wet electrodes should be kept for 3-4 hours to dry naturally.

The wastage may be almost negligible.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

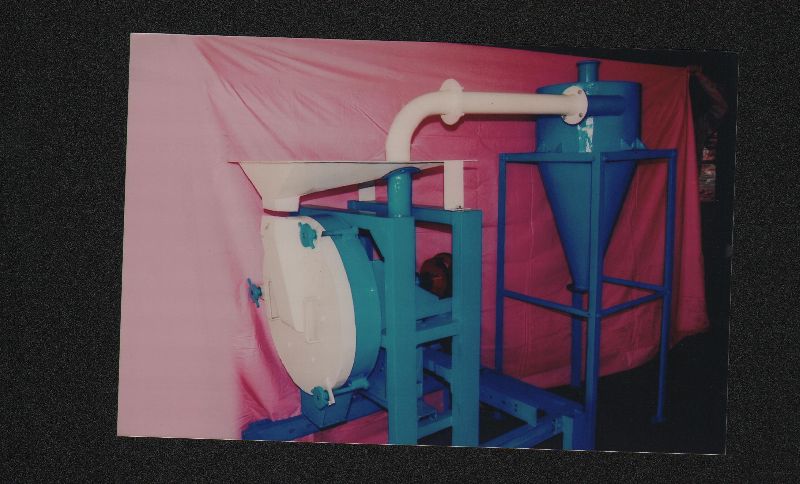

| Features | Robust Construction, Pins Pulverizer with Hammers |

| Drum Dia | 600 mm |

| Weight of Machine | 250-300 Kgs |

| Size | Length 1300 mm x Width 760mm x Height 1300 mm (Approx.) |

| Motor | 3 H.P. Motor |

| Grinding Capacity | 150-300 kgs flux per hr. |

The Flux Pulverizer is a specially designed machine for reclaiming Flux from wastage flux generated during the extrusion process, so that the wastage flux can be re-used immediately in the same mix or in the subsequent mix.

During the extrusion of electrodes the normal wastage of flux occurs due to :

-

Leakage through the flux cylinder.

-

Excess flux falling near the conveyer.

-

Brushing waste.

-

Wet de-coating flux.

-

Residual from Extrusion Head.

The wastage when it directly used, gives serious eccentricity problem. By use of Wet Flux Pulverizer the entire wastage is ground finely and can be re-used for production without any eccentricity problem.

The wastage generated during the production process like Brushing and from Extrusion Head which become dry and can not be reused without making powder again. This is costly material and can be reused by grinding it. The Dry Flux Pulverizer specially designed for the Dry wastage.

| Business Type | Manufacturer, Exporter, Supplier |

| Finishing | Powder Coated |

| Usage | Industrial |

| Specialities | Durable |

| Material | Metal |

| Color | Blue |

| Driven Type | Electric |

| Type | Wet Electrodes |

| Business Type | Manufacturer, Exporter, Supplier |

| Feature | Easy To Operate, Good Capacity |

| Voltage | 230V |

| Automatic Grade | Automatic |

| Power | 3-6kw |

| Driven Type | Electric |

| Finish | Coated |